-

Veiligheidslichtgordensensoren

-

bewegingssensoren

-

Infraroodfotocelsensoren

-

Lijndetector

-

Veiligheidssensor voor de barrièrepoort

-

UHFlezer

-

RFID-kaartlezer

-

Parkeersysteem

-

bezoekerbeheersysteem

-

Toegangscontrolesysteem

-

Verzender en ontvanger met afstandsbediening

-

Draadloze deuropener

-

Verkeerslichtsysteem

-

Schakelaarknoop

-

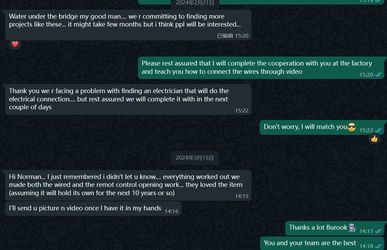

BurookHallo Norman... ik heb me net herinnerd dat ik je niet liet weten... alles werkte we hebben zowel de bedraad en de afstandsbediening opening werk...ze hielden van het item (veronderstelend dat het de komende 10 jaar of zo zal standhouden)

BurookHallo Norman... ik heb me net herinnerd dat ik je niet liet weten... alles werkte we hebben zowel de bedraad en de afstandsbediening opening werk...ze hielden van het item (veronderstelend dat het de komende 10 jaar of zo zal standhouden) -

Kiran.Jutai is een van de meest zelfverzekerde bedrijven die ik in China ken.

Kiran.Jutai is een van de meest zelfverzekerde bedrijven die ik in China ken.

Heavy Duty Dual Channel Loop Sensor voor het detecteren van vrachtwagens en bussen in parkeersystemen

| Stroomvereisten | 12-24V | Zelfdraaibereik | 20 tot 2000. |

|---|---|---|---|

| Gevoeligheid | 16-Way Selectable/ Hoogste 0,010% Dl/L/Laagste 2,56% | Operatie Temp | -40 ~ +70℃ |

| Reactietijden | Aan- en uitschakeling 10-90 ms | Specificatie | 13.6 maal 8.6 maal 5.2 |

| Markeren | sensoren voor zware lussen,twee-kanaallusdetector,sensor voor de detectie van vrachtwagenbussen |

||

JUTAI Heavy Duty Loop Sensor (LD-200/LD-202) is speciaal ontworpen voor het detecteren van vrachtwagens, bussen en grote voertuigen in parkeerinstallaties, tolhallen en industriële toegangscontrole.Met een hoge gevoeligheid en een verstelbare frequentie, zorgt deze JUTAI-lusdetector voor een betrouwbare detectie van de aanwezigheid van voertuigen, zelfs voor voertuigen met een te grote afmeting.

Belangrijkste toepassingen van de JUTAI-sensoren voor zware lussen:

✔ Parkeerplaatsen voor vrachtwagens en bussen ️ Grote voertuigdetectie voor barrièrepoorten

✔ Tolpleinen en snelwegen ️ spooropname van zware voertuigen

✔ Industrieel & magazijnspoorten ️ Monitoring van vorkheftrucks en vrachtwagens

✔ Logistiek en vrachtwagens

✔ Vliegvelden en militaire bases

Waarom is JUTAI de beste keuze?

- Truck & Bus Detection Hoog gevoelig voor grote voertuigen

- Dubbelkanaaloperatie CH1 & CH2 voor onafhankelijke detectie

- Verstelbare frequentie en gevoeligheid Optimaliseerd voor verschillende lussen

- Duurzaam en weerbestendig Gebouwd voor harde omgevingen buiten

Technische specificaties:

|

Kenmerken |

Detail |

|---|---|

| Merk. | Juutai. |

| Stroomvoorziening. | 100-240V wisselstroom (LD-200) / 12-24V gelijkstroom (LD-202) |

| Detectiemethode | Inductie-lus |

| Kanalen. | 2 (CH1 en CH2) |

| Output | Relais (NO/COM) |

| Types voertuigen | Trucks, bussen, aanhangwagens |

| Gevoeligheid. | Aanpassing op 8 niveaus (0,015% ∼0,8%) |

| Frequentie | 20KHz 100KHz (aanpasbaar) |

| LED-indicatoren | Vermogen (rood), detectie (groen) |

| Loopverbindingen. | CH1 (Pin 3,4), CH2 (Pin 5,6) |

| Relais contacten. | CH1 (Pin 10,11), CH2 (Pin 7,8) |

Verbindingen

Indicatoren en schakelaars:

- Power LED (RED): Verlicht om "Power ON" aan te geven.

- CH1-detectie-LED:

- Steady On: Toont voertuigdetectie aan.

- Langzaam knipperen: duidt op een kortsluiting of onvoldoende draaien na de lus.

- Snel knipperen: geeft aan dat er een open kring loopt of dat er na de lus overmatige draaien zijn.

- CH2-detectie-LED:

- Steady On: Toont voertuigdetectie aan.

- Langzaam knipperen: duidt op een kortsluiting of onvoldoende draaien na de lus.

- Snel knipperen: geeft aan dat er een open kring loopt of dat er na de lus overmatige draaien zijn.

Selectie van de gevoeligheid:

- Gevoeligheid en frequentieaanpassing worden vergemakkelijkt door middel van een 7-richtings- en 10-richtings-switchinstellingen.

- Gebruikers kunnen kiezen uit 8 verschillende gevoeligheidsinstellingen door de plaatsen van de schakelaar volgens de bijgeleverde tabellen in te stellen.

- Diepschakelaars 6, 7 en 8 regelen de CH1-gevoeligheid, variërend van 0,8 (minste gevoelig) tot 0,015 (meest gevoelig).

- De dipschakelaars 3, 4 en 5 regelen de CH2-gevoeligheid, variërend van 0,8 (de minst gevoelige) tot 0,015 (de meest gevoelige).

3. Schakelaar 1=S1 : Kanal 1 Loop Functie Selectie (10-weg dip schakelaar)

(1) ((Switch 1) DIP 1 & DIP 2 speciale gevoeligheidstoename voor beide aanhangwagens (beide kanalen).

(2)(Schakelaar 1=S1) D3, D4, D5 en (Schakelaar 2=S2) D1, D2 Speciale instellingsfuncties (modus1, 2, 3 richtingsdetectie. modus 4, 5, 6 Normale modus, twee lusdetectie gescheiden)

(3)(Schakelaar 1=S1) D6 & D7 & D8 en (Schakelaar 2=S2) D3 & D4 & D5 Instelling van CH1- en CH2-gevoeligheidsselectie (keuzes op acht niveaus).

(4)(Schakelaar 1=S1) D9 & D10 en (Schakelaar2=S2) D6, D7 Instellingsfrequentie (20 K tot 100 KHz).

* Resetknop: Let op: De LD-200 moet elke keer opnieuw worden ingesteld wanneer de dipschakelaars worden gewijzigd.

Installatievoorzieningen en probleemoplossing:

- De grootte van de spoel en de inbouwrichtlijnen zijn zoals weergegeven in het diagram aan de rechterkant.

- Het wordt aanbevolen om voor de inductie spoel ferromagnetische draden te gebruiken met een totale lengte van maximaal 500 meter.

- De snijgrootte van de spoel moet een rechthoek zijn met een lengte van 1,0 tot 2,0 meter en een breedte van 0,8 tot 1,2 meter, waarbij zo veel mogelijk rechte hoeken bij de hoeken worden vermeden.

- Aanbevolen installatie-overzicht van typische basisspiraaldraaiingen:

Bij de installatie moet de stekker en het stopcontact van het product in verticale richting staan

Toepassing

De JUTAI LD200/202 dubbelkanaal voertuiglusdetectorserie, uitgerust met richtingherkenningsfunctie, is ideaal voor talrijke enkelkanaalscenario's voor in- en uitgang.Wanneer geïntegreerd met de JUTAI One-door controller (model: AC-11), JUTAI-poortbarrière (model: BR-110) en JUTAI-langeafstands-RFID-lezer (model: PUHF-9), samen met hoogtemperatuurresistente lusspellen (model: JTHT-11),het vormt een naadloze oplossing voor toegangscontrolesystemen met een enkelkanaal.

Het werkingsprincipe is als volgt:

-

Inschrijvingsproces:

- Wanneer een auto de buurt of de parkeerplaats binnenkomt, worden de twee lusspellen tegelijkertijd ingedrukt.

- De JUTAI Double Channel Loop Detector (LD-200/202) activeert de UHF-lezer aan de ingang.

- De UHF-lezer leest de kaart-ID en stuurt deze via Wiegand-uitgang naar de controller (AC-11).

- De controller verifieert de geldigheid van de ID en geeft een relaissignaal om de poortbarrière te openen.

- De auto komt in de gemeenschap of op de parkeerplaats en als hij de barrière passeert, daalt de barrièrearm automatisch.

- De JUTAI Single Channel Loop Detector (LD-100/102) zorgt tijdens dit proces voor veiligheid en anti-smashingfunctionaliteit.

-

Uitgangsproces:

- Als een auto de buurt of de parkeerplaats verlaat, passeert ze een UHF-lezer.

- De LD-200/LD-202 activeert de UHF-lezer, die de kaart leest en de ID naar de controller stuurt.

- De controller verifieert de geldigheid van de ID en geeft een relaissignaal om de poortbarrière te openen zodat de auto kan vertrekken.

- Als de auto door de barrière gaat, daalt de barrièrearm automatisch.

- De LD-100/102 biedt tijdens dit proces veiligheid en anti-schudfunctionaliteit.

-

Richtingsherkenning:

- De richtingherkenningsfunctie van de LD-200/LD-202 zorgt ervoor dat de dubbelkanaallusdetector het signaal niet opnieuw activeert wanneer de auto langs een andere UHF-lezer gaat.waarbij alleen de in- of uitgangsgegevens in het systeem worden opgenomen.

De JUTAI LD-200/202 Double Channel Loop Detector kan ook functioneren als twee onafhankelijke enkelkanaalslusdetectoren.waarbij zowel bij de ingang als bij de uitgang één barrière en één langeafstandslezer aanwezig zijn.

In deze opstelling wordt één lusspiraal gebruikt om de lezer te activeren en de kaart te lezen, terwijl de andere lusspiraal is gewijd aan de anti-vermorzelen functie van de barrière.Door de LD-200/202 te gebruiken als twee onafhankelijke lusdetectorenDeze opstelling vermindert een deel van de hardware kosten die verbonden zijn aan het gebruik van afzonderlijke detectoren voor elke functie.

Deze functionaliteit wordt bereikt door de functie van de onafhankelijke werkstand van de LD-200/202 in te schakelen, waardoor deze in deze dubbele capaciteit effectief kan werken.

![]()

![]()